Materials Handling and Storage

Online Training Certification Course

29 CFR 1910 Subpart N & 29 CFR 1926 Subpart H

From the highest rated and most trusted online training company - since 2008.

Materials handling training topics include both general and specific safety measures to reduce the risk of workplace injury. This course provides an overview of general safety requirements, safety measures related to equipment, and employer/employee rights and responsibilities to manage, handle, move, and store materials safely.

Moving, handling, and storing materials are common occurrences in workspaces, but these actions can be dangerous if not done properly. Every year, numerous back, hand, and arm injuries are attributed to incorrectly lifting, carrying, or storing materials. This online training course provides important safety practices for employees who handle, lift, and move materials manually or with mechanical equipment.

This course is for:

Manual and material handling procedures exist in most workplaces. This materials storage training course is designed for anyone whose work operations include moving, storing, and disposing of worksite materials.Mishandling materials is the single largest cause of accidents and injuries in the workplace. This safety training may help prevent serious injury in the workplace and save lives.

Case Study: In New York in 2018, a worker was renovating a building when he was struck by debris that fell from a trash chute. The chute had become clogged with waste materials at the third-floor level; two workers (including the victim) went inside the dumpster at the end of the chute in order to clear the debris. It took the combined efforts of local police officers, firefighters, and paramedics to free the victim, who was then taken to a local hospital in critical condition.

Key Takeaway: Recognize the many dangers related to trash chutes. The OSHA standard focused on workers being struck by falling debris, but this unfortunate incident is a reminder that chutes pose other dangers, such as being clogged and collapsing.

Available languages: 100+ languages - translation provided by Google Translate (Select Language bottom of page)

Governing Regulations

The Occupational Safety and Health Act of 1970 created the Occupational Safety and Health Administration (OSHA). OSHA, an agency of the U.S. Department of Labor, is charged with the enforcement of safety and health conditions of workers through the use of regulations published in the Code of Federal Regulations. OSHA regulations are published in Title 29 of the Code of Federal Regulations. Part 1910 covers general industry regulations, while 1926 is designated for construction industry standards.

This online certification course is based on the regulations set forth in OSHA 29 CFR 1926 Subpart H, as well as OSHA 29 CFR 1910 Subpart N. Both subparts address safety standards for construction and general industry related to materials handling, storage, use, and disposal.

What You'll Learn

- General Safety Requirements

- Ergonomics

- Fire Safety

- Aisles and Passageways

- Training and Education

- Proper Lifting Techniques

- Moving, Stacking, and Storing Materials

- Before Moving, Handling and Storing Materials

- Personal Protective Equipment

- Blocking Materials

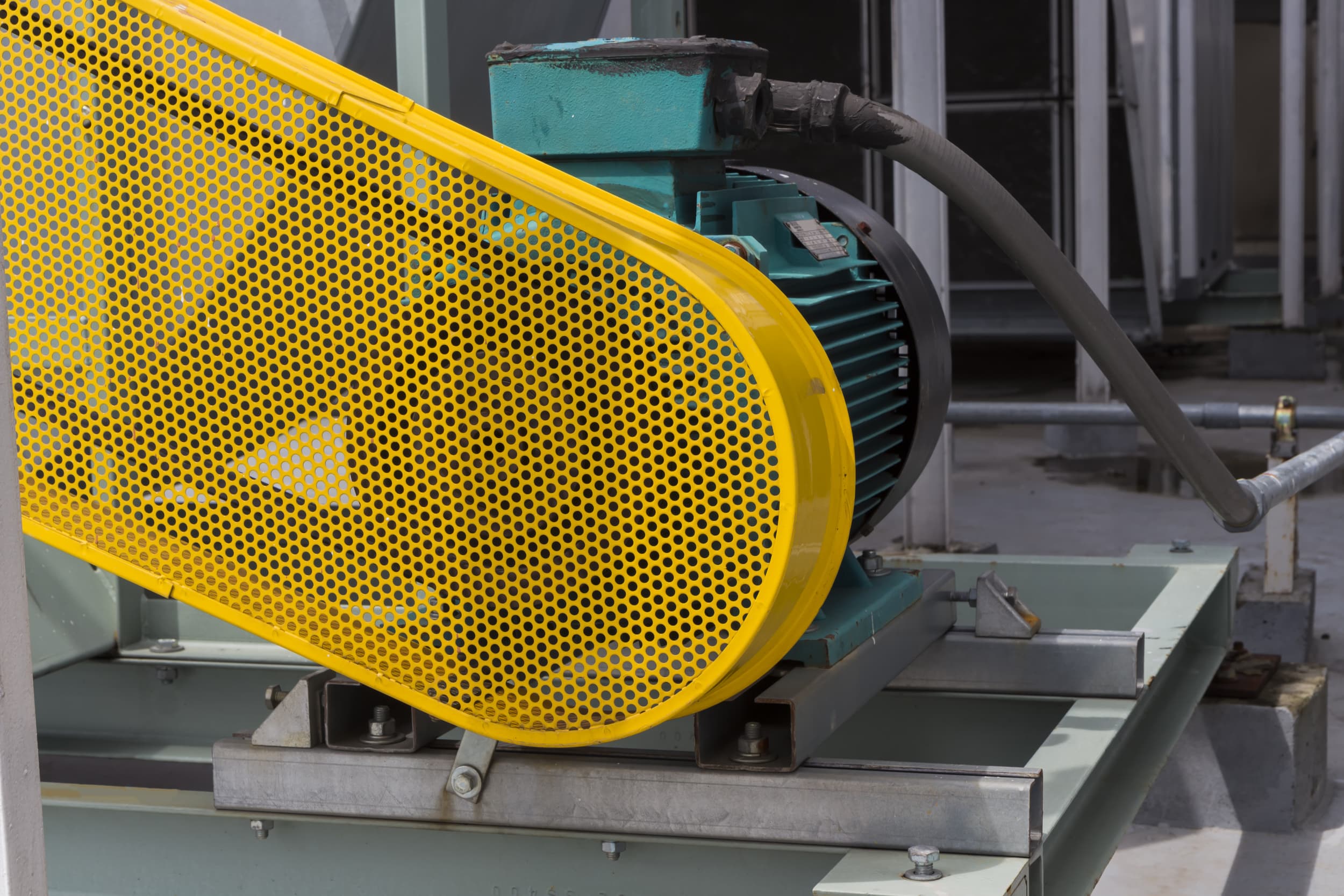

- Mechanical Equipment

- Stacking and Storing with Powered Equipment

- Equipment (Conveyors, Cranes, Slings, and Trucks)

- Safety Measures Related to Conveyors

- Safety Measures Related to Cranes

- Safety Measures Related to Slings

- Industrial Trucks - Safety Measures Related to Industrial Trucks

- Industrial Trucks - Design

- Industrial Trucks - Modifications

- Industrial Trucks - Designations D and E

- Industrial Trucks - Designations G and L

- Industrial Trucks - Unsafe Working Conditions

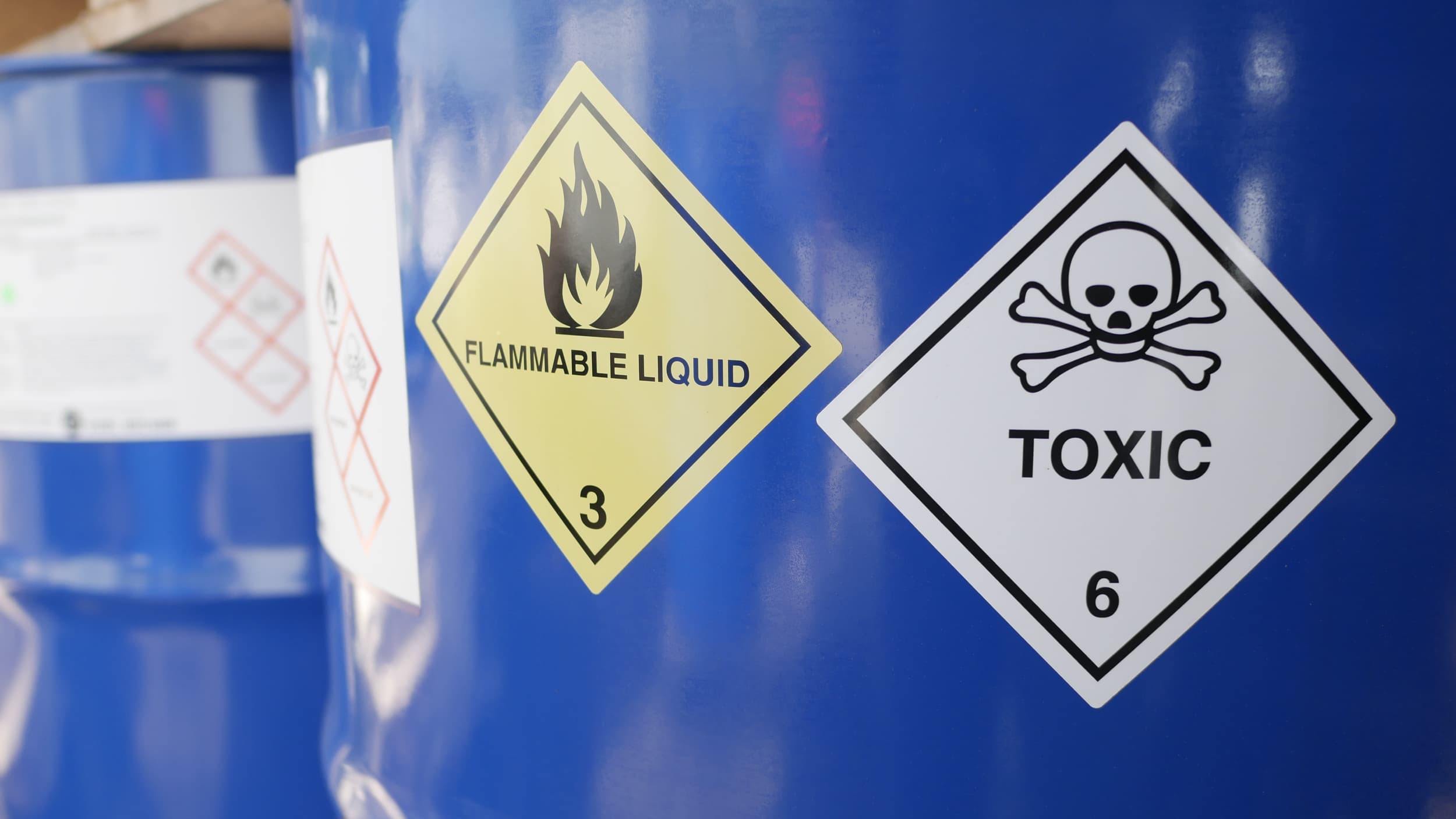

- Industrial Trucks - Flammable Vapors or Dusts in Working Conditions

- Industrial Trucks - Operating and Maintaining

- Industrial Trucks - Hazards Related to Batteries

- Industrial Trucks - Operating and Maintaining Battery-Charging Stations

- Industrial Trucks - Training Requirements

- Rights and Responsibilities

- Employer Responsibilities - Equipment

- Employee Rights

- Employee Responsibilities

- OSHA and Whistleblower Protection

- Rigging Equipment

- Slings

- Alloy Steel Chains

- End Attachments

- Sling Inspections

- Wire Rope Slings

- Shackles and Hooks

- Synthetic Webbing

- Synthetic Webbing Environmental Conditions

- Splicing - Fiber Rope Slings

- Splicing - Rope Sling Splices

- Rigging Equipment - Safe Operating Temperatures

- Rigging Equipment - Removal from Service

- Storage

- General Guidelines

- General Guidelines - Bricks and Blocks

- General Guidelines - Lumber

- Housekeeping

- Dockboards

- Disposal of Waste Materials

- Disposal of Waste Materials at an Elevation - Chutes

- Disposal of Waste Materials - Holes

- Disposal of Waste Materials - Scrap Items

- Disposal of Waste Materials - Flammable Items and Items to Burn

- Summary

- Additional Resources

- Exam

It will take a MINIMUM of 2 hours to complete this online course. The student may log on and off as needed. A bookmark will be set so when they log back in they will return to where they left off.

We have no restrictions on how long a person takes to complete a course. Likewise, if you are purchasing for others, we have no time limit on assigning courses, so you can purchase a larger quantity than you currently need and take advantage of volume discounts.

Employers are responsible for training new personnel before assigning them to tasks that may expose them to hazards such as managing, handling, moving, and storing materials.

This materials storage and handling training course covers various OSHA regulations and retraining requirements differ for each. It is important to note these differences and comply with OSHA's recommendations.

To ensure compliance with 29 CFR 1910 Subpart N, safety training must be conducted when an operator has been observed operating the vehicle in an unsafe manner, involved in an accident or near-miss incident, assigned to drive a different type of vehicle, and/or changed workplace conditions affect safe materials handling operations.

Under the General Duty Clause of the OSH Act, safety training must be conducted periodically and as-needed to ensure the work environment is free from recognized hazards. Refresher training should also occur whenever changes to the worksite, equipment, or tasks render previous training obsolete.

This materials handling and storage certification course meets these training requirements.

Each student will receive 0.2 CEUs (or 2 CMEs) from Compliance Training Online® for completing this course.

Sean W

Materials Handling and Storage SafetyThe course was evenly spread out which made it not feel like too much reading and the questions accurately summed up the course

Alberto G

Materials Handling and Storage SafetyGreat!!!

Philip L

Materials Handling and Storage SafetyCourse was informative about safety, responsibilities, and specifics about vehicles and storage. This will help to place an emphasis on an area of concern. Thank You.

THE BEST ONLINE TRAINING EXPERIENCE POSSIBLE

Fast

Your time is valuable. We've designed our site to be as fast as possible.

Easy to use

You'll never get lost or confused with us.

Immediate Access

There's no waiting period. Begin the course as soon as you sign up.

Anywhere Anytime

Internet connection and a computer, tablet, or smartphone.

Up to date

We update our courses as soon as new regulations come out.